412 Fabricated Steel Tapping Sleeves |

|||||||||||||||||||||||||||||||||||||||||||||||||||

|

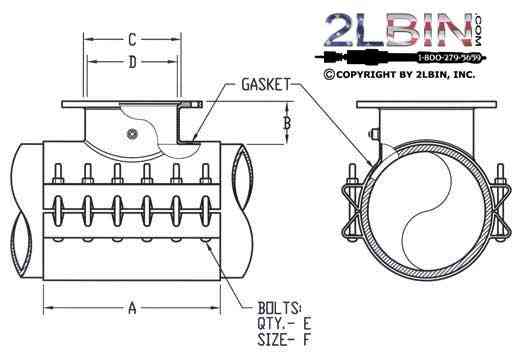

Built-in range assures proper fit on more than one class of pipe; reducing inventory requirements and alignment recesses for sleeve and tapping valve. Comes complete with corrosion resistant, high-strength, low-alloy bolts, and eliminates the chance of not having the right size sleeve. Ease of assembly eliminates extra equipment, time, and specially trained personnel. Ready availability means taps can be made without long delays; even taps on special sizes of pipe or services requiring high pressure flanges. The direct reinforcement of the pipe, by the sleeve, eliminates flexing or deflection of the pipe opposite the tap. Weighs less than heavy cast iron sleeves, which reduces the load on the pipe. Most important, 412 Tapping Sleeves assure a safe dependable tap. A large gasket cross section provides a positive initial seal, which improves with increases in line pressure. ** Data obtained using 20 mil natural coatings. Addition of pigments may cause varying results. Limitations - Not suitable for hydrocarbon service. Normal Service: -20° F to 160° F Immersion Service: <125°F Special Approvals - Meets ANSI/NSF Standard 61 for potable water service. Classified by UL (Underwriters Laboratories, Inc.) HOW TO ORDER 412 Tapping Sleeves1. Determine O.D. of Pipe. 2. Select proper sleeve O.D. range. 3. Specify sleeve number and outlet size. Epoxy with alloy bolts, add (E) Example: For A/C pipe with 14.21 O.D. with 6” outlet, epoxy coated with stainless bolts, order: 412-1420 x 6 ESS LARGER SIZES AND OUTLETS AVAILABLE For outlets 14” and larger, the tapping valve to be used must be specified to assure proper alignment recess dimension. 412 Tapping Sleeves furnished with test plugs unless otherwise specified. *These sizes not available with size on size outlets. For size on size outlets a 1/2” undersize shell cutter is required.

|

|||||||||||||||||||||||||||||||||||||||||||||||||||

412 Fabricated Tapping Sleeve Specifications: |

412 Tapping Sleeve Installation Instructions

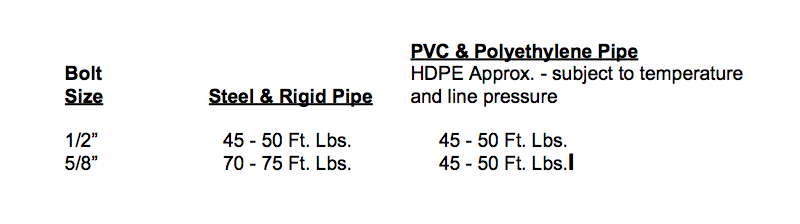

Pipe sizes 6” - 12” -100 ft. lbs. of torque. Pipe sizes 14” & larger -125 ft. lbs. of torque NOTE: For test and working pressure above 250 PSI bolts must be tightened to 150 - 170 ft. lbs. of torque. (Contact for proper application.) On Thin Wall, PVC (SDR21, 26), and Flexible Pipe 50 - 55 ft. lbs. minimum HDPE SDR11, SDR17 -6” - 12” 60 ft. lbs. minimum HDPE SDR11, SDR17 -14” and Larger 90 ft. lbs. minimum

Note: Size on size tapping cutter must not be larger than recommended by pipe manufacturer. Also, tapping operation must not force the pipe away from the gasket seal. Service Saddle Installation Instructions

|

|

Heavy Duty Torque Wrench and Extra Deep 4 Piece Socket Set

| But it Now | Part # | Price |

|---|---|---|

Click the following link if you need more information on Tapping Saddle Torque Wrench |

||

Click the following link if you need more information on Tapping Saddle Torque Socket Sets |

||

412 DOUBLE STRAP SERVICE SADDLES

*All sales final for tapping saddles sold, Prices change without notice, effective 1-1-2011| NOM. PIPE SIZE (IN.) | SLEEVE O.D. RANGE (IN.) | SLEEVE NUMBER X ANY OUTLET | OUTLET SIZES AVAILABLE | APPR. WT. EACH (LBS.) |

|---|---|---|---|---|

| 6 | 6.63 6.83 - 7.16 7.05 - 7.40 7.40 - 7.73 |

412-0690 412-0720 412-0745 |

X 3 X 4 X 6 |

74 76 82 |

| 8 | 8.63 8.98 - 9.37 9.27 - 9.69 |

412-0905 412-0940 |

X 3 X 4 X 6 X 8 |

83 85 88 118 |

| 10 | 9.83 - 10.25 10.64 - 10.86 11.03 - 11.47 11.36 - 11.80 11.76 - 12.24 |

*412-1000 412-1075 412-1110 412-1140 412-1200 |

X 3 X 4 X 6 X 8 X 10 |

90 92 96 125 168 |

| 12 | 12.62 - 12.88 13.13 - 13.60 13.60 - 14.09 14.08 - 14.56 |

412-1275 |

X 3 X 4 X 6 X 8 X 10 X 12 |

98 100 104 140 176 216 |

| 14 | 14.59 - 15.08 15.23 - 15.80 15.73 - 16.22 16.30 - 16.73 |

412-1475 412-1530 412-1600 412-1650 |

X 3 X 4 X 6 X 8 X 10 X 12 |

113 115 116 150 190 220 |

| 16 | 16.74 - 17.26 17.33 - 17.87 17.88 - 18.43 18.62 - 19.19 |

412-1684 412-1740 412-1800 412-1875 |

X 3 X 4 X 6 X 8 X 10 X 12 |

113 115 120 162 210 230 |

| 18 | 18.87 - 19.45 19.41 - 20.01 20.00 - 20.60 20.29 - 20.94 20.93 - 21.57 |

412-1920 412-1950 412-2000 412-2050 412-2130 |

X 3 X 4 X 6 X 8 X 10 X 12 |

120 122 126 180 240 245 |

| 20 | 21.51 - 22.15 22.16 - 22.81 22.78 - 23.45 23.46 - 24.16 24.15 - 24.85 24.82 - 25.52 |

412-2160 412-2254 412-2294 412-2400 412-2450 412-2502 |

X 3 X 4 X 6 X 8 X 10 X 12 |

131 133 140 185 245 255 |

| 24 | 25.71 - 26.41 26.55 - 27.25 27.26 - 27.96 28.14 - 28.84 |

412-2580 412-2715 412-2746 412-2834 |

X 3 X 4 X 6 X 8 X 10 X 12 |

143 143 160 215 280 312 |

| 30 | 29.78 - 30.48 30.48 - 31.18 31.52 - 32.22 |

412-3000 412-3075 412-3200 |

X 3 X 4 X 6 X 8 X 10 X 12 |

163 165 175 226 295 310 |

Leave us a Facebook Comment

Heavy Duty JCM 905 Torque Wrench

Heavy Duty JCM 905 Torque Wrench Extra Deep 4 Piece Socket Set and Case

Extra Deep 4 Piece Socket Set and Case