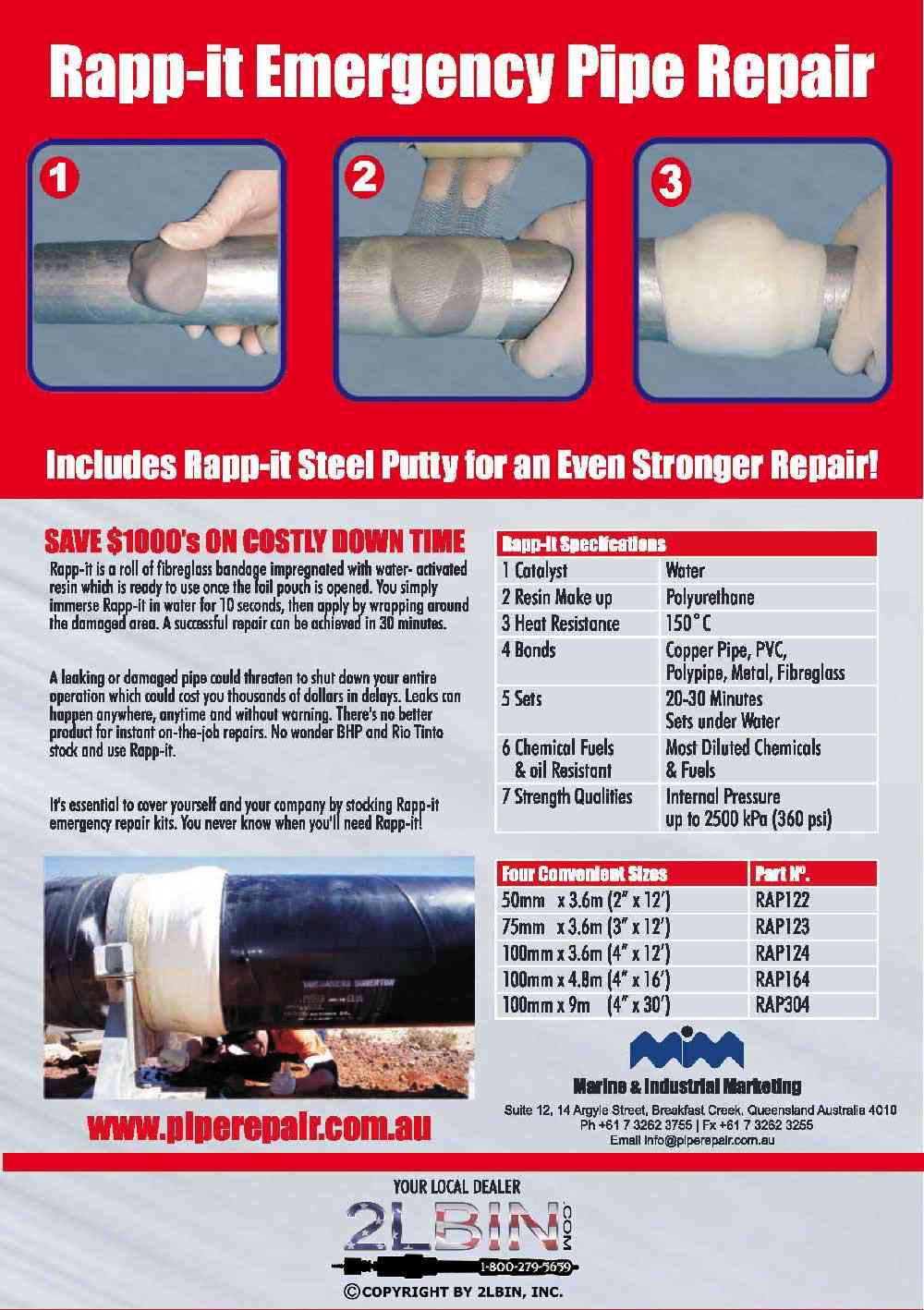

Rapp-it Emergency Pipe Repair |

||

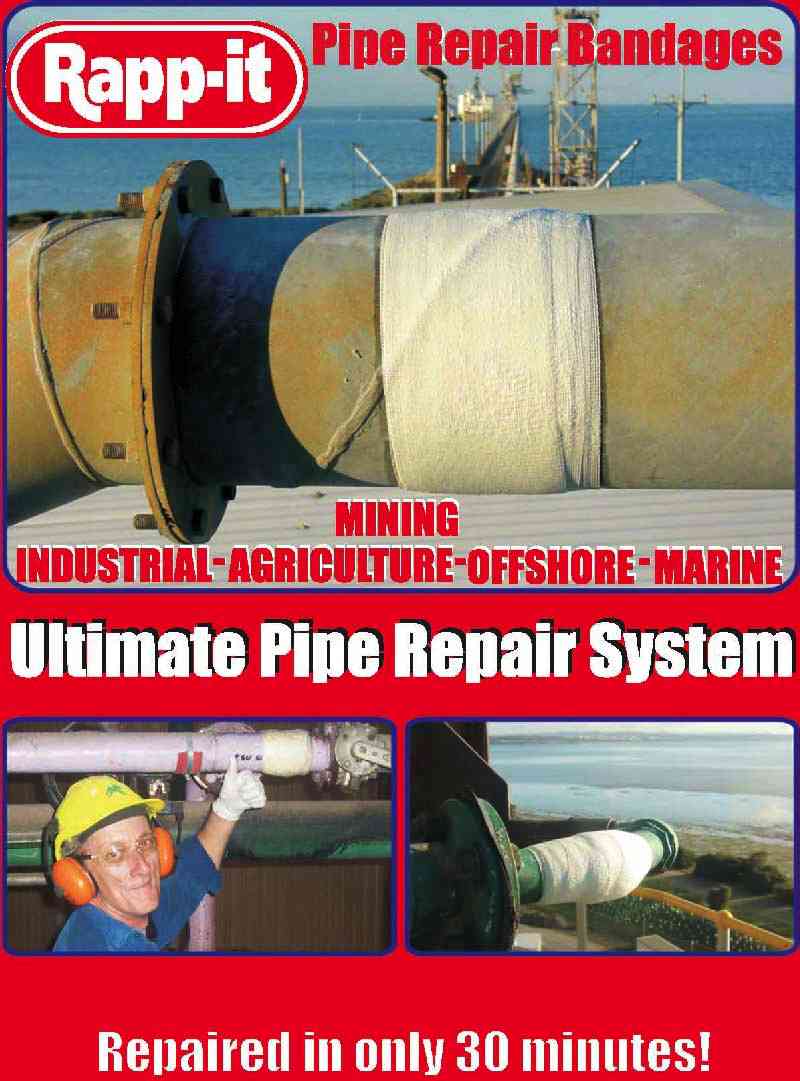

Applications A leaking pipe could threaten to shut down your entire operations, which could cost thousands of dollars in downtime, so it pays to cover yourself and your company by keeping a packet or two of Rapp-It on hand. Installation Instructions It is important that you choose the correct size for your application.

Temperature rating is 150 Degrees and it is recommend putting two bandages on for pressures over 100 PSI.

Please refer to Rapp-It instructions for use on each package for the problem and solution guide.

|

||

Rapp-it Pipeline Leakseal Video:

Rapp-it Pipe Repair Bandages |

||||||

|

||||||

| Size | Part # | Price |

| 50mm x 3.6m (2" x 12´) | 2lbin-RAP-122 | $ 50.50 each |

| 75mm x 3.6m (3" x 12´) | 2lbin-RAP-123 | $ 52.50 each |

| 100mm x 3.6m (4" x 12´) | 2lbin-RAP-124 | $ 60.30 each |

| 100mm x 4.8m (4" x 16´) | 2lbin-RAP-164 | $ 72.20 each |

| 100mm x 9m (4” x 30’) | 2lbin-RAP-304 | $ 102.50 each |

Leave us a Facebook Comment