502 Stainless Steel Hot Tapping Service Sleeve |

||

|

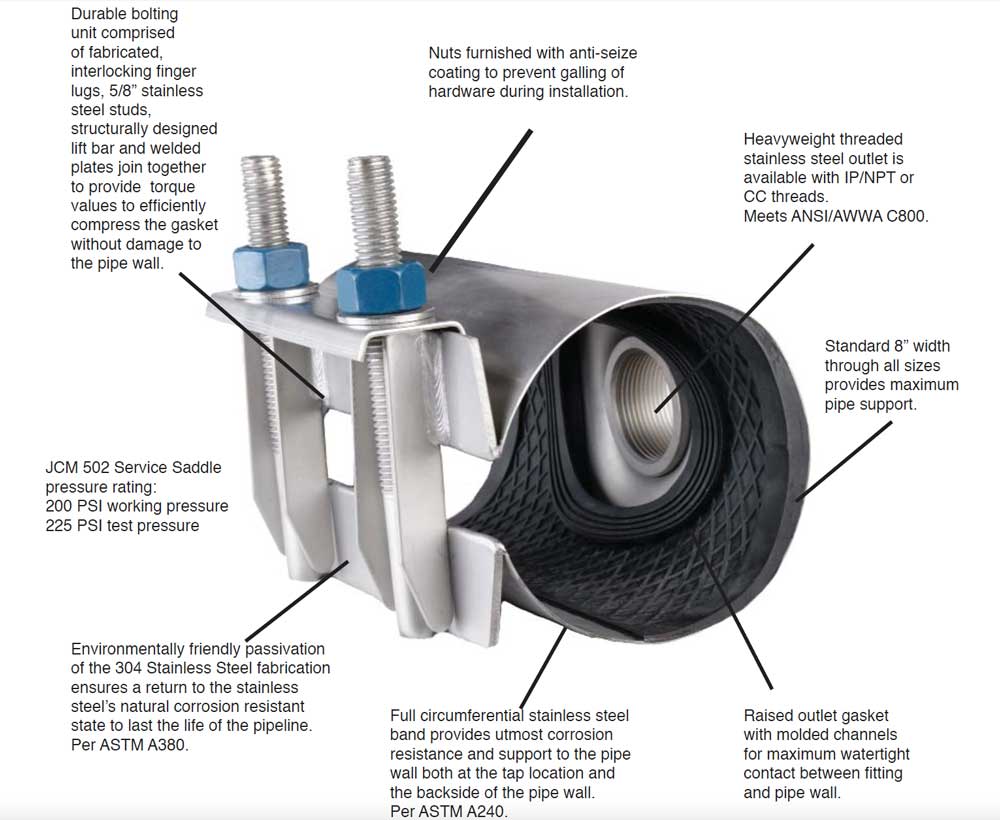

Responding to industry requests for a better product, JCM introduces the Model 502 Stainless

Steel Service Saddle. The JCM 502 Stainless Steel Service Saddle is engineered with the

pipe in mind. Heavy duty construction with balanced bolt design provides the pipe support,

bolt torque and gasket compression necessary for a successful, long term saddle installation. JCM 502 Stainless Steel Service Saddle Material Specifications Recommended

For: IPS PVC, C-900 PVC, Ductile Iron, Cast Iron, Steel and other types of pipe.

|

||

502 Double Strap Service Saddle Specifications: |

Single band service saddle shall have a minimum material standard of 18-8 Type 304 stainless steel band, bolt assembly and hardware. Fabricated lug shall have permanently attached mutually supporting fingers and strong stainless steel lifter bar plate. Stainless steel studs, two (2) or three (3), shall be 5/8” and furnished with stainless steel washers to ensure proper torque readings. Stainless steel nuts will be coated with anti-seize coating to prevent galling. The gasket shall be EPDM material, gridded with raised outlet gasket with molded channels, and permanently adhered to the stainless steel band. Service saddle shall be minimum 8” in width. The stainless steel outlet shall be attached to the band by TIG weld process. Service saddle will be passivated per ASTM A380 with environmentally friendly process to return stainless to natural corrosion resistant state. Gaskets shall be tapered to maximum 1/4” thickness. Service saddles shall be JCM 502 or approved equal.

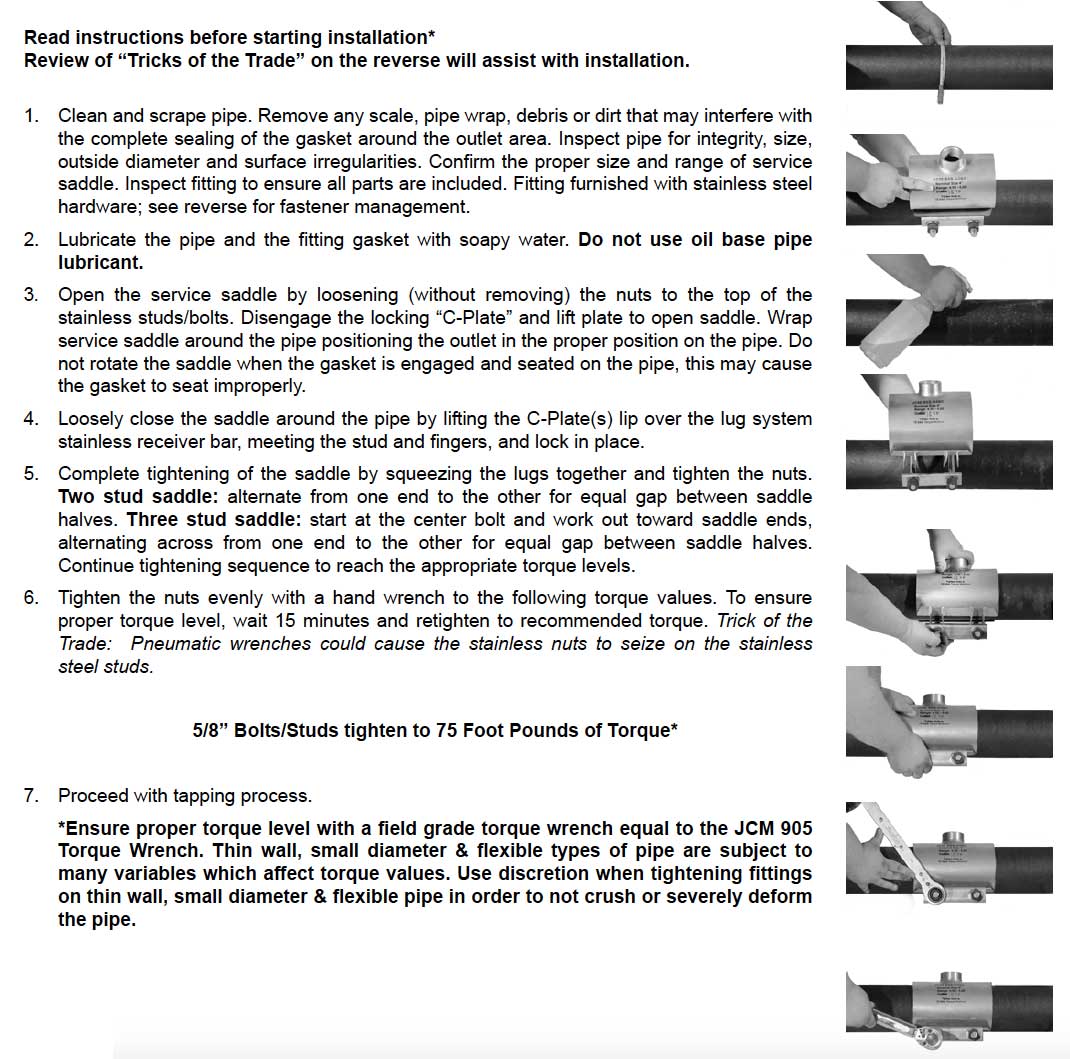

1. Clean and scrape pipe. Remove any scale, pipe wrap, debris or dirt that may interfere with the complete sealing of the gasket around the outlet area. Inspect pipe for integrity, size, outside diameter and surface irregularities. Confirm the proper size and range of service saddle. Inspect fitting to ensure all parts are included. Fitting furnished with stainless steel hardware; see reverse for fastener management. 2. Lubricate the pipe and the fitting gasket with soapy water. Do not use oil base pipe lubricant. 3. Open the service saddle by loosening (without removing) the nuts to the top of the stainless studs/bolts. Disengage the locking “C-Plate” and lift plate to open saddle. Wrap service saddle around the pipe positioning the outlet in the proper position on the pipe. Do not rotate the saddle when the gasket is engaged and seated on the pipe, this may cause the gasket to seat improperly. 4. Loosely close the saddle around the pipe by lifting the C-Plate(s) lip over the lug system

stainless receiver bar, meeting the stud and fingers, and lock in place. 6. Tighten the nuts evenly with a hand wrench to the following torque values. To ensure proper torque level, wait 15 minutes and retighten to recommended torque. Trick of the Trade: Pneumatic wrenches could cause the stainless nuts to seize on the stainless steel studs. 5/8” Bolts/Studs tighten to 75 Foot Pounds of Torque* 7. Proceed with tapping process. |

Heavy Duty Torque Wrench and Extra Deep 4 Piece Socket Set

| But it Now | Part # | Price |

|---|---|---|

Click the following link if you need more information on Tapping Saddle Torque Wrench and Socket Sets |

||

Click the following link if you need more information on Tapping Saddle Torque Wrench and Socket Sets |

||

502 Stainless Steel Service Saddle

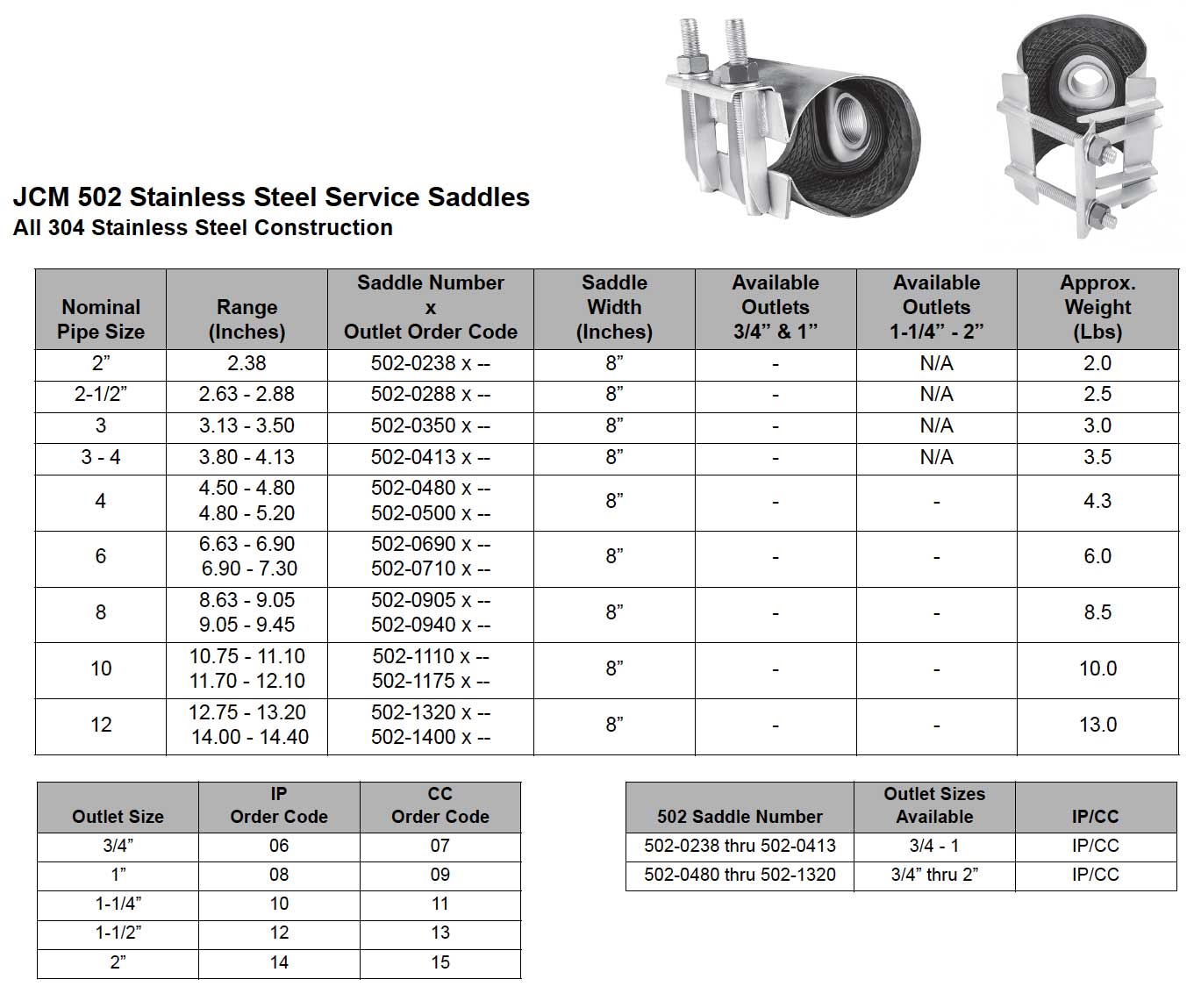

*All sales final for tapping saddles sold, effective 1-1-2011| NOM. PIPE SIZE (IN.) | PIPE O.D. RANGE (IN.) | BASE CATALOG NUMBER X ADD TAP CODE | APPR. WT. EACH (LBS.) |

|---|---|---|---|

2 |

2.38” |

502-0238 X - |

2.5 |

2-1/2 |

2.63” - 2.88” |

502-0288 X - |

3 |

3 |

3.13" - 3.50" |

502-0350 X - |

3.5 |

3 - 4 |

3.80" - 4.13" |

502-0413 X - |

4 |

4 |

4.50" - 4.80" |

502-0480 X - |

5 |

4 |

4.80" - 5.20" |

502-0500 X - |

5 |

5 |

5.13" |

502-0513 X - |

10 |

6 |

6.13" |

502-0613 X - |

6.5 |

6 |

6.63” – 6.90” |

502-0690 X - |

10 |

6 |

6.90” – 7.30” |

502-0710 X - |

10 |

8 |

8.13" |

502-0813 X - |

12 |

8 |

8.63” – 9.05” |

502-0905 X - |

13 |

8 |

9.05” – 9.45” |

502-0940 X - |

13 |

10 |

10.75” – 11.10” |

502-1110 X - |

14 |

10 |

11.70” – 12.10” |

502-1175 X - |

14 |

12 |

12.75” – 13.20” |

502-1320 X - |

14 |

12 |

14.00” – 14.40” |

502-1400 X - |

14 |

| NOM. PIPE SIZE (IN.) | PIPE O.D. RANGE (IN.) | BASE CATALOG NUMBER X ADD TAP CODE | APPR. WT. EACH (LBS.) |

|

|||

Leave us a Facebook Comment

Heavy Duty JCM 905 Torque Wrench

Heavy Duty JCM 905 Torque Wrench Extra Deep 4 Piece Socket Set and Case

Extra Deep 4 Piece Socket Set and Case