452 All Stainless Steel Tapping Sleeve with Outlet Seal Gasket |

||

|

The 452 All Stainless Steel Tapping Sleeve incorporates the heavy duty design of the fabricated steel tapping sleeve with the corrosion resistance of all stainless steel. This heavy design utilizes a broad cross section, hydro-mechanical outlet gasket in lieu of the full body gasket. This outlet gasket provides a positive seal, which improves with an increase in line pressure. The 452 has been engineered for installations requiring higher working pressure, higher safety precautions, or longer service life than standard all stainless or cast iron sleeves; and is manufactured to provide superior corrosion resistance applications on mains, which are not subject to beam breaks. Heavy all stainless tapping sleeves offer extra benefits.All Stainless Construction - All stainless steel construction provides extra corrosion resistance. The stainless steel flange, outlet, and body join as one unit of similar metals, to assure the highest structural strength and long-term corrosion resistance. Heavy Duty Design: Heavier construction and thicker metal provide extra reinforcement of the pipe and outlet. The extra bolting power and body thickness eliminate problems inherent with lightweight sleeves. High Pressure Capability –Exceptionally Safe - The broad, heavy, hydro-mechanical gasket provides for high-working pressure applications. They are also ideal for critical problem prone taps such as pump stations, large diameter mains, and large outlets.Large Sizes - High Pressure -The premier sleeve for larger sizes of ductile iron, PVC, PE and steel pipe. High-pressure sleeves are available on request. Stronger - Yet Lighter Than Cast Sleeves - Reduced weight aids in installation and handling as well as reducing load on the pipe. Extra Wide for Support and Stability - Extra width, and heavier neck and body material, provide extra reinforcement of the outlet, and extra stability during the tapping process.Affordable - These all stainless sleeves are surprisingly affordable in all sizes. Larger sleeves are priced less than ductile iron mechanical joint sleeves which offer less corrosion resistance and pressure capability.

|

||

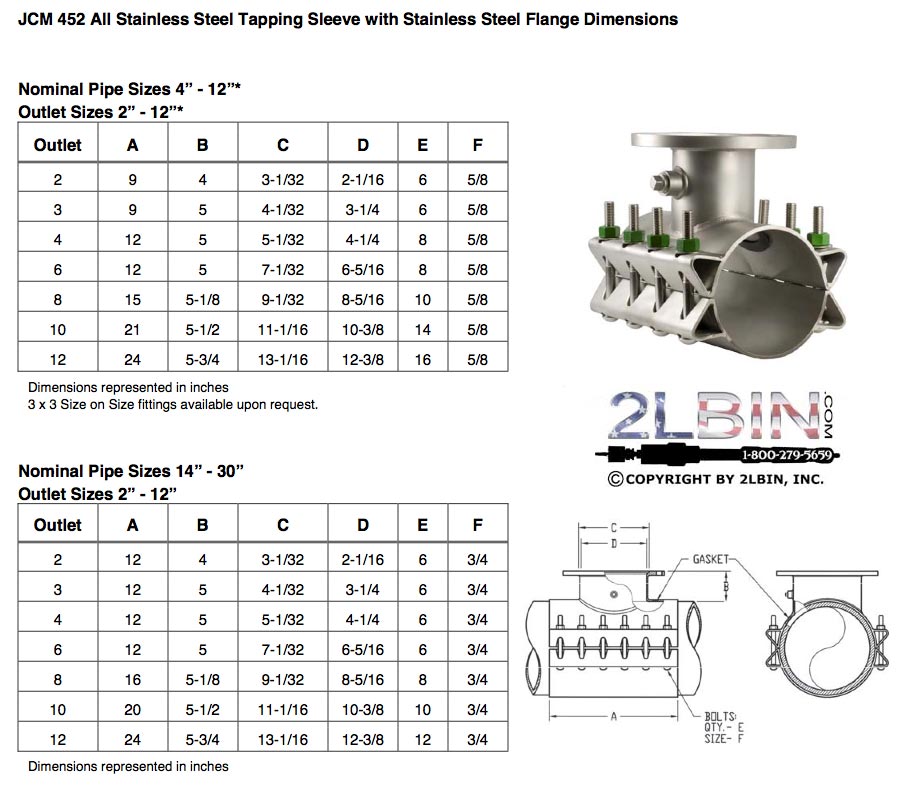

452 Stainless Steel Saddle Specifications: |

|

The 452 All Stainless Steel Tapping Sleeve is especially recommended for applications involving large diameters, high working pressures, and fluctuating line pressures in corrosive or acidic environments. Direct compression of the gasket provides maximum sealing capability for high or fluctuating pressures. For pricing and engineering, the following information must be furnished:

452 All Stainless Steel Tapping Sleeve - Typical Specification 452 All Stainless Steel Tapping Sleeve - Material Specification BODY: Stainless Steel 18-8 Type 304. Optional 316 Stainless Steel. BOLTS: Stainless Steel 18-8 Type 304. Optional 316 Stainless Steel. FLANGE: CF8 Cast Stainless Steel or equivalent 304 Stainless Steel. Flange outlets shall be indexed per MSS-SP60 to accept tapping valve. Optional 316 Stainless Steel. GASKET: Compounded for use with water, salt solutions, mild acids, and bases. SERVICE RATING: 4” - 12” Outlets: 175 PSI. Service rating of 250 PSI or higher available with specified flange. |

|

Heavy Duty Torque Wrench and Extra Deep 4 Piece Socket Set

| But it Now | Part # | Price |

|---|---|---|

Click the following link if you need more information on Tapping Saddle Torque Wrench |

||

Click the following link if you need more information on Tapping Saddle Torque Socket Sets |

||

452 All STAINLESS STEEL SERVICE SADDLES

*All sales final for tapping saddles sold, effective 1-1-2011| NOM. PIPE SIZE (IN.) | SLEEVE O.D. RANGE (IN.) | SLEEVE NUMBER X ANY OUTLET | OUTLET SIZES AVAILABLE | APPR. WT. EACH (LBS.) |

|---|---|---|---|---|

| 4 | 4.50 4.80 |

452-0450 452-0480 |

X 3 X 4 |

32 32 |

| 6 | 6.63 6.83 - 7.16 7.05 - 7.40 7.40 - 7.73 |

452-0663 452-0690 452-0720 452-0745 |

X 3 X 4 X 6 |

74 76 82 |

| 8 | 8.63 8.98 - 9.37 9.27 - 9.69 |

452-0863 |

X 3 X 4 X 6 X 8 |

83 85 88 118 |

| 10 | 9.83 - 10.25 10.64 - 10.86 11.03 - 11.47 11.36 - 11.80 11.76 - 12.24 |

*452-1000 452-1075 452-1110 452-1140 452-1200 |

X 3 X 4 X 6 X 8 X 10 |

90 92 96 125 168 |

| 12 | 12.62 - 12.88 13.13 - 13.60 13.60 - 14.09 14.08 - 14.56 |

452-1275 |

X 3 X 4 X 6 X 8 X 10 X 12 |

98 100 104 140 176 216 |

| 14 | 14.59 - 15.08 15.23 - 15.80 15.73 - 16.22 16.30 - 16.73 |

452-1475 452-1530 452-1600 452-1650 |

X 3 X 4 X 6 X 8 X 10 X 12 |

113 115 116 150 190 220 |

| P. O. A. Call 2lbin 800-279-5659 or 405-745-2637 | ||||

| 16 | 16.74 - 17.26 17.33 - 17.87 17.88 - 18.43 18.62 - 19.19 |

452-1684 452-1740 452-1800 452-1875 |

X 3 X 4 X 6 X 8 X 10 X 12 |

113 115 120 162 210 230 |

| P. O. A. Call 2lbin 800-279-5659 or 405-745-2637 | ||||

| 18 | 21.51 - 22.15 22.16 - 22.81 22.78 - 23.45 23.46 - 24.16 24.15 - 24.85 24.82 - 25.52 |

452-1920 452-1950 452-2000 452-2450 452-2130 |

X 3 X 4 X 6 X 8 X 10 X 12 |

120 122 126 180 240 245 |

| P. O. A. Call 2lbin 800-279-5659 or 405-745-2637 | ||||

| 20 | 21.51 - 22.15 22.16 - 22.81 22.78 - 23.45 23.46 - 24.16 24.15 - 24.85 24.82 - 25.52 |

452-2160 452-2254 452-2294 452-2400 452-2450 452-2502 |

X 3 X 4 X 6 X 8 X 10 X 12 |

131 133 140 185 245 255 |

| P. O. A. Call 2lbin 800-279-5659 or 405-745-2637 | ||||

| 24 | 25.71 - 26.41 26.55 - 27.25 27.26 - 27.96 28.14 - 28.84 |

452-2580 452-2715 452-2746 452-2834 |

X 3 X 4 X 6 X 8 X 10 X 12 |

143 143 160 215 280 312 |

| P. O. A. Call 2lbin 800-279-5659 or 405-745-2637 | ||||

| 30 | 29.78 - 30.48 30.48 - 31.18 31.52 - 32.22 |

452-3000 452-3075 452-3200 |

X 3 X 4 X 6 X 8 X 10 X 12 |

163 165 175 226 295 310 |

| P. O. A. Call 2lbin 800-279-5659 or 405-745-2637 | ||||

| NOM. PIPE SIZE (IN.) | SLEEVE O.D. RANGE (IN.) | SLEEVE NUMBER X ANY OUTLET | OUTLET SIZES AVAILABLE | APPR. WT. EACH (LBS.) |

Leave us a Facebook Comment

Heavy Duty JCM 905 Torque Wrench

Heavy Duty JCM 905 Torque Wrench Extra Deep 4 Piece Socket Set and Case

Extra Deep 4 Piece Socket Set and Case