415 Concrete Steel Cylinder Pipe Saddles |

|

|

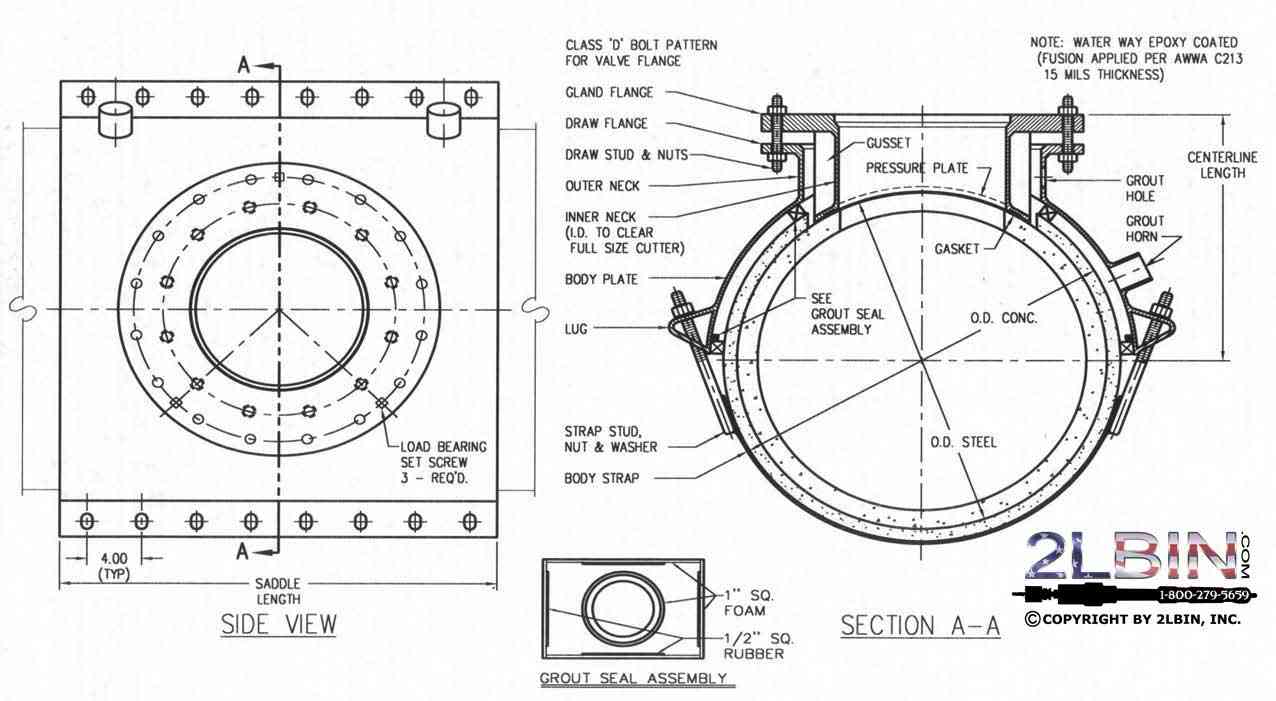

The 415 tapping sleeve for "Concrete Steel Cylinder Pipe" is the standard in the industry for fast and safe taps on concrete pressure pipe. Designed to meet the AWWA M-9 Manual, the 415 is the leading sleeve preferred by PCCP tapping contractors. These fabricated tapping sleeves are designed to reinforce the pipe and provide for easy installation and maximum safety. There are many unique features as well as options available on these sleeves. Unique to these sleeves are the following: separate body and tapping outlets, broad cross section gaskets, gusseted pressure plates, combination gland/draw flanges, load bearing set screws, grout seal assemblies, and epoxy coated waterways. Separate Body and Tapping Gland (outlet) - By separating the outlet gland from the sleeve body the sleeve reinforces the pipe prior to removal of the critical prestress wire from the outlet area. Broad Cross Section Gasket - The 7/8” wide gasket with a hydromechanical lip provides a broad sealing surface, which produces an initial seal that improves with increases in line pressure. The broad, flat gasket is exceptionally advantageous for sealing on beveled cylinder welds. Gusseted Pressure Plate - The gusseted pressure plate eliminates problems caused by flexing of the cylinder or tapping sleeve pressure plate. This grooved plate is contoured to fit the cylinder and retains the broad profile gasket to provide an extra margin of safety at this critical point. Combination Gland/Draw Flange - The combination gland/draw flange on 4” - 12” outlet sizes facilitates tapping with a 25” travel tapping machine. Larger outlets utilize separate flanges for each function to make bolt take-up on large flanges more accessible. Load Bearing Set Screws - The 415 Tapping Sleeve is furnished with load bearing set screws on the gland flange that are tightened after the gland is installed. These set screws tighten against the sleeve draw flange, transferring any load on the outlet away from the steel cylinder and onto the sleeve. Grout Seal Assembly -Type 415 Tapping Sleeve, the standard sleeve, is furnished with straps and a grout seal assembly under the sleeve. These two design features facilitate fitting oversize, undersize, and out-of-round pipe by providing the means to pour cement grout into a cavity to make a perfect sleeve fit. This feature is in accordance with the AWWA M-9 manual, as recommended by the manufacturers of concrete pressure pipe. Epoxy coated sleeves, and sleeves with a solid back, sit directly on the pipe, precluding the use of the grout seal assembly. Epoxy Coated Waterway - The tapping sleeve’s waterway is fusion applied epoxy coated to provide a quality connection protected against corrosion in the critical waterway HOW TO ORDERFor pricing and engineering, the following information must be furnished:

FOR SLEEVES FOR REINFORCED CONCRETE PIPE ASK FOR 412 TAPPING SLEEVES FOR REINFORCED CONCRETE PIPE.

|

|

415 Concrete Steel Cylinder Pipe Saddle Specifications: |

|

415 Tapping Sleeve for Concrete Steel Cylinder Pipe - Typical Specification Tapping Sleeves for Concrete Steel Cylinder Pipe shall be in accordance with AWWA Manual M-9. They shall also meet AWWA C-301 and C-303 Standards pertaining to design, manufacturing quality tests, and welders qualifications. Manufacturers shall have manufactured this type of tapping sleeve for a minimum of ten (10) years. The sleeves shall have a separate gland which permits installation of the sleeve prior to the cutting of the prestress wires. The gland shall have a fusion epoxy coated (per AWWA C-213) waterway, and a minimum 7/8” wide hydro-mechanical gasket, set in a retaining machined groove of a pressure plate. For outlet sizes 14” and larger, the gasket groove must be consistently positioned about throat of the tapping waterway. The inside diameter of the gasket groove must be set back a minimum of 1” from the waterway to allow for the dispersal of forces generated by the gasket compression. Gasket grooves machined in a circle and formed to an elliptical shape will not be an accepted equivalent. The pressure plate shall be gusseted to the draw flange, which eliminates flexing. The gland shall be equipped with load bearing set screws to protect the cylinder. Sleeves shall be furnished with grouting seals and grout horns to facilitate filling the space between the sleeve and the pipe. Tapping sleeves shall be ANSI/NSF Standard 61 Certified. Tapping Sleeves shall be a 415 Tapping Sleeve or an approved sleeve of equal quality.

|

|

Heavy Duty Torque Wrench and Extra Deep 4 Piece Socket Set

| But it Now | Part # | Price |

|---|---|---|

Click the following link if you need more information on Tapping Saddle Torque Wrench |

||

Click the following link if you need more information on Tapping Saddle Torque Socket Sets |

||

Leave us a Facebook Comment

Heavy Duty JCM 905 Torque Wrench

Heavy Duty JCM 905 Torque Wrench Extra Deep 4 Piece Socket Set and Case

Extra Deep 4 Piece Socket Set and Case